+7(495) 660 94 49 (многоканальный номер)

8 (800) 250 94 49 (бесплатный для регионов)

- Certification Of Specialists

- Laboratory Accreditation

- NDT Devices & Means

- Calibration Of NDT Funds

ECOSCAN 35 - complex of digital radiography

| Retail | checkout at the office; |

| Online Starter* | entry level benefits; |

| Online 1..5* | five steps: more orders - more benefits; |

| Online Wholesale* | maximum benefit; |

| Online VIP* | individual discount. |

* valid only for orders placed on the site, according to the standard templates of contracts and accounts, it is mandatory to accept the Confidentiality Conditions for the information of an individual offer

Ecoscan 35 wireless digital radiography complex is designed for non-destructive testing of industrial products by direct digital radiography. The use of the Ecoscan 35 complex eliminates the use of x-ray film and the need to maintain equipment and facilities for its chemical processing, interpretation and subsequent storage. The complex can be used in the control of hard-to-reach objects in the field and in the factory without the use of additional power sources.

The principle of operation of the Ecosсan 35 complex is based on the registration of X-ray radiation passing through the object of control and falling on the matrix of a flat-panel detector with its further conversion into a digital signal and obtaining an image on a personal computer screen that is available for further processing, analysis and storage.

The detector's scintillator converts the X-rays into visible light, which is received by the photodiode array. The analog electrical signal from each element of the photodiode array is converted by an analog-to-digital converter (ADC) into a digital format. The higher the bit depth of the ADC, the more shades of gray you can get. Further, the digital image is transmitted via wired or Wi-Fi connection to the operator's computer. Specialized software "Strazhnik" allows to carry out operational control of the complex and decipher the received image of the monitored object.

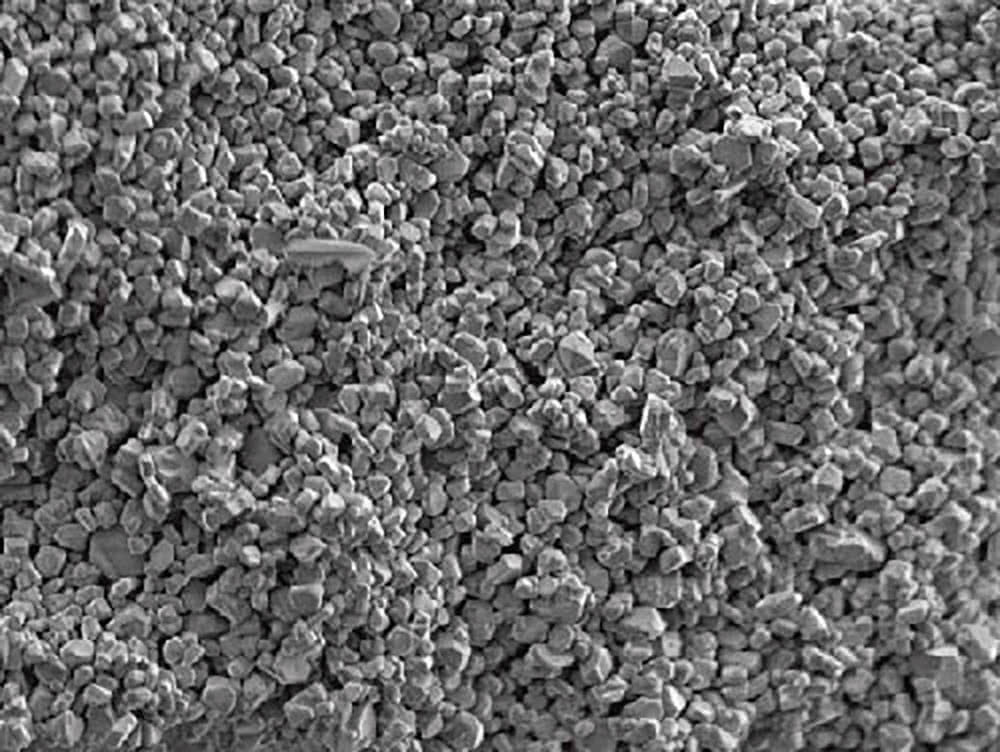

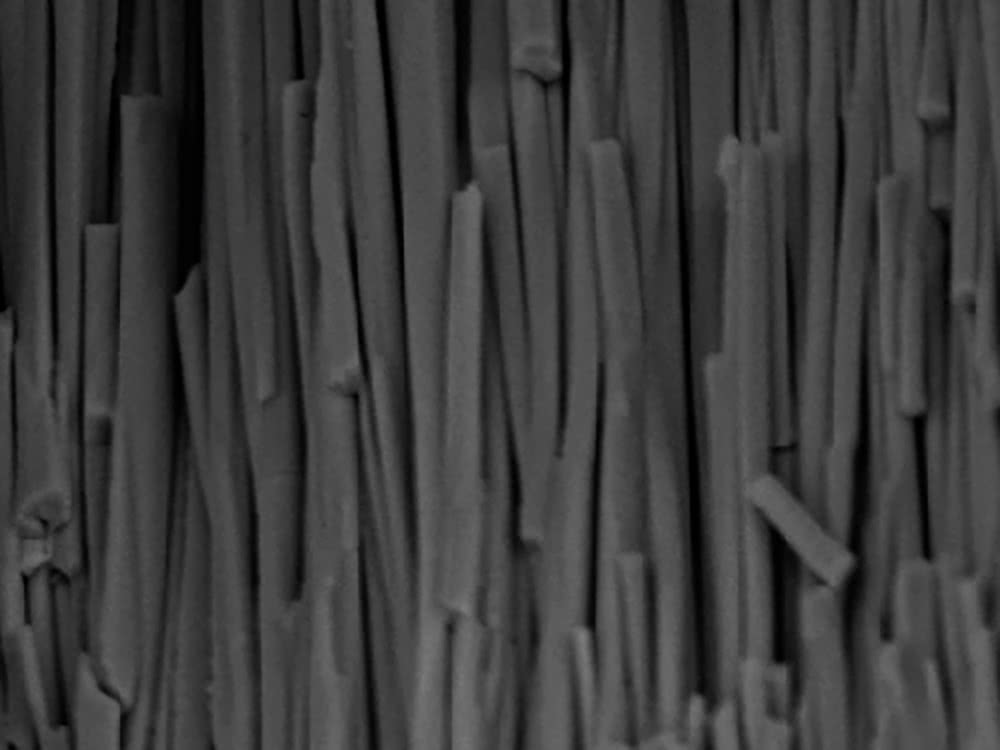

Depending on the problem being solved, the detector scintillator can be made of gadolinium oxysulfide (Gadox) or cesium iodide (Csl). Gadox has a granular structure, is less sensitive to X-rays (compared to Csl) and can be used under conditions where X-rays inevitably hit the working area of the detector, bypassing the test object. The single-crystal structure of the Csl-based scintillator is much more sensitive to X-ray radiation, which makes it possible, under the same control conditions and with the same image quality, to make an exposure 3–4 times faster and to control products of great thickness. However, the use of a Csl-based scintillator is not recommended in case of possible direct exposure of the X-ray radiation to the working area of the detector or in case of a significant difference in the thickness of the test objects. This is due to the "memory" effect of the crystal structure of cesium iodide when exposed to direct X-rays. White spots resulting from overexposure disappear only after a long period of time - from several hours to several days or even weeks, depending on the parameters of the exposure made. Therefore, a Csl-based scintillator is only recommended for testing objects that have a uniform or close to uniform radiation thickness, such as welded seams of large diameter pipes.

- no need to use consumables and equipment for film development significantly reduces the cost of radiographic control;

- short payback period of the complex even with small amounts of control;

- archiving the received images in digital format;

- high speed of obtaining the result compared to other methods of radiographic control, the flaw detector operator can start analyzing the image immediately after the end of the exposure;

- wide functionality and choice of software tools speeds up the processing of the resulting image and ensures reliable detection of defects;

- the option of tracking the location of equipment by GPS allows you to fix the coordinates of the place of control and automatically save them in the image parameters without the possibility of editing;

- A flat-panel detector is much more sensitive to X-rays than an X-ray film, which can significantly save the life of the X-ray machine by reducing the required exposure time.

- a wide range of detectors with different sizes of the effective working area and dimensions, created on the basis of various technologies of matrices and scintillators, allows solving a wide range of problems in the field of industrial non-destructive testing;

- high sensitivity of the detector and wide dynamic range make it possible to control the product even if the object is in operation (presence of the product inside the pipelines, the outer layer of insulation, etc.);

- the detector is powered both from AC mains and from replaceable batteries;

- an additional set of batteries as part of the complex allows you to increase the battery life and perform control without the need to stop for recharging the batteries;

- the components of the complex are protected from the influence of external factors, such as direct ingress of moisture and dust, and have high mechanical strength during physical impact during installation and transportation of equipment;

- a special protective cover dampens possible shocks when the detecting unit is placed on the test object;

- the X-ray sensor built into the detecting unit allows you to take pictures automatically after the start of the exposure;

- the internal memory of the detector allows you to accumulate and combine the obtained images for further processing, without requiring communication with the control station of the flaw detection operator;

- The flat-panel detector is adapted to work with both constant-potential X-ray machines and pulsed X-ray machines.

- automatic determination of the basic spatial resolution by duplex wire standard;

- building a profile showing the levels of change in grayscale to analyze the quality and uniformity of the image;

- building a histogram showing the distribution of pixels in grayscale to optimize the contrast of individual areas of the image;

- combining the frames accumulated during the exposure to form an image of better quality;

- automatic measurement of the normalized signal-to-noise ratio;

- changing the gain level of the signal received by the detector - used to avoid oversaturation of the gray level in the image if it is not possible to change the exposure mode of the X-ray machine;

- calibration of the detector by offset, gain and dead pixels helps to improve the quality of the resulting image depending on the exposure mode;

- image processing to improve the convenience of image decoding - changing the brightness, contrast, gamma correction either manually or using a set of ready-made filters (minimum and maximum alignment, sharpening, relief);

- linear measurements on a scale set by the operator, determination and measurement of thinning or thickening of the material;

- archival storage of data in the protected DICONDE format with subsequent creation of files in other formats (BMP, JPEG, TIFF).

- DICONDE format images modified on third-party devices are marked with a special symbol that protects images from unwanted editing;

- an intuitive interface will not cause difficulties in deciphering and processing images, even for beginners;

- the ability to import external regulatory databases for working with defects and the formation of reports filled out based on image processing according to a pre-created template.

Ecoscan 35 digital radiography complex includes:

- static portable flat panel x-ray detector,

- protective case,

- control station of the flaw detector operator with pre-installed software "Strazhnik",

- a wireless access point that serves as an intermediate link between the control station and the detector in the absence of the possibility of establishing a direct wireless connection.

Thanks to the use of an industrial tablet computer, as well as an autonomous power supply system for the detector based on two sets of replaceable batteries, the complex is completely portable. The components of the complex are protected from the influence of external factors, such as direct ingress of moisture and dust, and have high mechanical strength during physical impact during installation and transportation of equipment. For additional protection of the detector, a protective cover is used, which dampens possible shocks when the detecting unit is placed on the test object.

The protective cover has the ability to position on the object of control using straps that can either cover the object or stretch on special magnetic fasteners.

- flat panel detector;

- system control unit (Wi-Fi/Ethernet);

- a set of additional detector batteries (2 pcs.);

- detector battery charger

- rugged tablet with pre-installed software "Strazhnik";

- tablet case with stylus;

- laptop with pre-installed software "Guardian";

- transport case;

- housing PPD with a device for fastening to the object of control;

- power cable from the mains 220 V - 2 pcs.;

- passport and instruction manual;

- Software "Strazhnik" *;

- heating element for operation at low temperatures with a power supply*;

- stand-alone power supply unit ELITEST ECO-24*;

- two-wire standard Duplex IQI-D13 Kowotest (ISO 19232-5, ASTM E 2002)*;

- magnetic wheels ECO-10MK*;

- belt fastening ECO-10RK*;

- magnetic holders ECO-10MD*.

* - advanced kit (until the end of 2022 included in the basic kit).

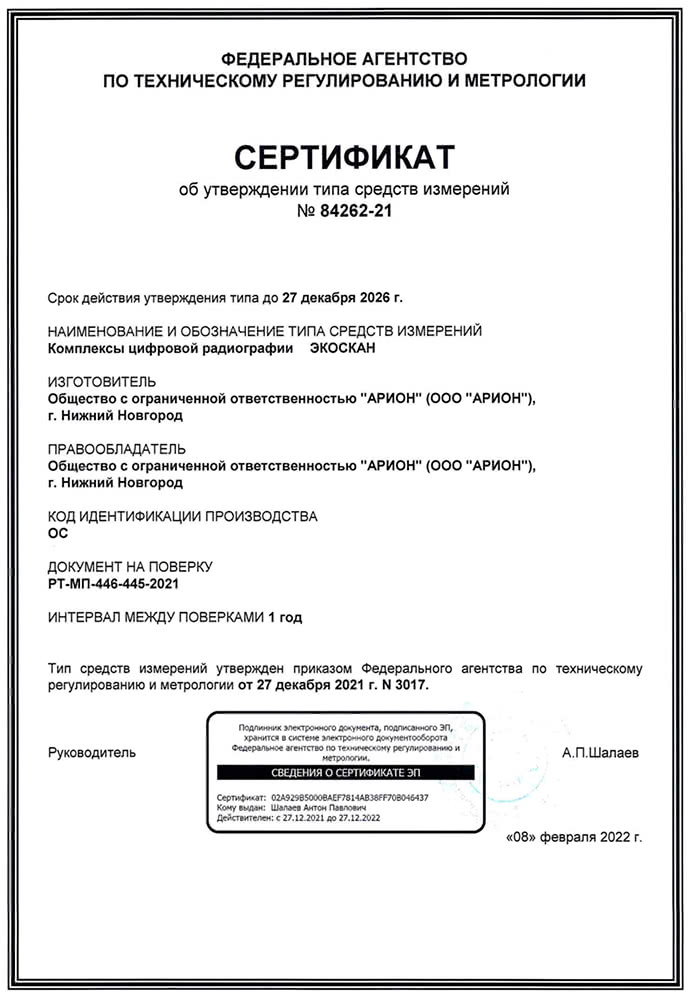

Compliance with standards:

- Type approval certificate for measuring instruments No. 84262-21 dated 02/08/2022 issued by Federal Agency for Technical Regulation and Metrology.

| Описание типа СИ |

| ECOSCAN 35 (базовый комплект) | ECOSCAN 35 (CsI) | |

Measurement parameters | ||

| Range of registered energy of gamma radiation, keV | from 40 to 450 | |

Optical system | ||

| Photodiode Array Technology | a-Si TFT | |

| Scintillator type | Gadox | CsI |

| Pixel Pitch, µm | 100 | |

| Number of pixels | 3 534 x 4 302 | |

Control parameters | ||

| Effective zone size, mm | 350,3 x 430,0 | |

| Minimum distance from the matrix to the outer boundaries of the detector on the short side, mm | 9,5 | |

Transducer | ||

| Bit depth of analog-to-digital converters, bit | 16 | |

Environmental protection | ||

| International protection marking | IP67 | |

Dimensions and weight | ||

| Weight, kg | 7,000 | 7,000 |

| Body (Height x Width x Length), mm | 17,0 x 400 x 470 | |

Operating conditions | ||

| Operating temperature range, °C | from -20 to +40 | |

There are no reviews for this product yet.. Write the first review.